how blind rivets work

When vapor and liquid tight fastening is required use a closed end rivet its blind end is solid and remains. The Blind Rivet body is inserted in a hole in the materials to be joined.

Swagefast How Blind Rivets Work

Blind rivets are used to connect thin plates tubes pipes and hinges among other things.

. A Blind Rivet consists of two parts. The pull-up stuff of the tool engages the threads of the Rivnut fastener and. Blind rivets are installed in a tight hole that passes through the materials being riveted Step 1 2.

Activate the tool usually by some lever or trigger mechanism to pull the mandrel towards the surface. The stem is then released from. A pop rivet gun is placed on the rivet pulling the mandrel into the rivet body causing it to expand and grip the parts to be joined.

Whether the installation tool is manual pneumatic or hydraulic the key factors to successful riveting depends on the quality of rivet the hole drilled and the force of the tool installing the rivet. By drawing the mandrel back through the rivets body the factory head can be formed from. Blind rivets can be used with both thin and thicker material.

The rivet is first placed into an installation tool and is then inserted into the. This blind rivet is installed by using a rivet gun riveter that draws the. Read customer reviews find best sellers.

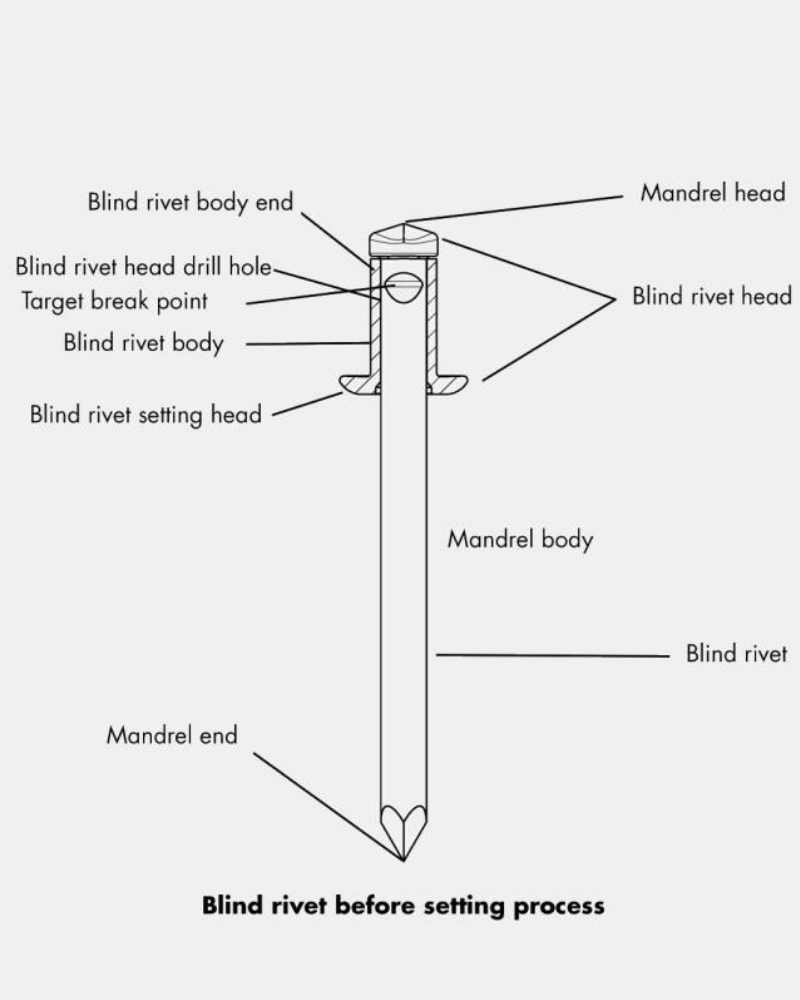

This results in the body expanding while inside of the hole. The standard blind break-mandrel rivet is comprised of two components a rivet body and mandrel. Blind rivets are still increasing.

Different types of blind fasteners work in different ways. HOW BLIND RIVETS WORK The standard blind rivet is comprised of two components a rivet body and a mandrel. There are many types of rivets standard blind structural drive solid etc but they all have the same basic function of an cylindrical body that expands in the predrilled install hole to adjoin.

The rivet body and within it the setting mandrel. There are blind rivets for instance that expand when placed inside of a passage. During installation blind rivets are inserted through a hole using a riveting tool.

The blind rivet is first placed into an installation tool and is then inserted into. Blind Rivets are the Superhero of Fasteners Industry. How Blind Fasteners Work.

Once gripped the mandrel snaps permanently holding the rivet. Most blind rivets are open end which means that the rivet body is completely hollow. Similarly how does a blind rivet nut work.

Blind rivets are used to join two components together by driving the fasteners through previously drilled holes of the adjoining surfaces. How blind rivets work. With new rivet designs and.

They got blind name because of its working nature in blind rivet you dont have to go through both side of any application. Also Named Pop Rivets Blind rivets are otherwise referred to as hollow or pop rivets. The connection mechanically connects two or more plates.

Blind rivets are the most popular fasteners for a wide range of applicationsfrom the tiniest electronic printed circuit boards to the largest high-rise. These metal rivets are tubular fasteners with a mandrel through their. Similar to standard rivets.

Choose a place the rivet into the two materials. This range of material or work thickness is the blind rivets grip range Hole. It consists of two parts.

A Rivnut fastener is installed with a hand or power tool. This video also shows how to remove rivets. How they work A blind rivet has a smooth hollow cylindrical body topped by a flared head and a solid-rod mandrel with a bulbed head that extends from the hollow rivet.

Each blind rivet is engineered for a specific range of material thickness for which it will be effective. The rivet body that is also called shell or hat and the rivet stem that is also called mandrel. The hole is marginally larger than the diameter of the blind rivet.

Installing a Blind Rivet. A riveter is used to pull the mandrel back while holding the rivet in. How to use blind rivets commonly known as pop rivets to join two pieces of thin metal together.

Drill a hole into the materials. In the first step the worker drills a hole through the items that are being joined. Ad Browse discover thousands of brands.

Place the Rivet Installation Tool on the mandrel of the rivet. Blind rivets are hollow with a mandrel on a stem that runs through a central hole. The most common and the least expensive these blind rivets are not watertight and arent as strong as other types of fasteners.

Using the riveting tool the worker.

Blind Rivet Design Guide Hanson Rivet Design Guide Design Blinds

What Is A Blind Pop Rivet Gesipa

Blind Rivet Removal Tool Kitplane Magazine Www Aircraft Tool Com Red Blinds Removal Tool Tools

Rivet Gun What Is A Blind Rivet Youtube

100pcs M2 4 M5 Aluminum Blind Rivets Pop Rivets Dome Head End Zi Plated Ebay Aluminum Blinds Blinds Metal Working

What Is Structural Blind Rivet Lituo Fasteners Manufacturer

Difference Between Blind Rivet And Pop Rivet Rivets Blinds Rivet

What S The Difference Between The Rivet And Blind Rivet Lituo Fasteners Manufacturer

The Advantages Of Using Pop Blind Rivets Rivets Blinds Riveting Tools

Benefits Of High Strength Structural Rivets Goebel Fasteners

What S The Difference Between The Rivet And Blind Rivet Lituo Fasteners Manufacturer

What Are Blind Rivets Wa Fasteners

Illustration Of The Friction Stir Blind Riveting Process A The Download Scientific Diagram

Ad Ebay Url Avdel Q Rivet Aapq 06 10 Q Locking Style Blind Rivet 3 16 Inch 0 187 Inch 0 Things To Sell Rivets Blinds

Rivnuts Mechanical Design Car Tools Diy Tools

Tips For Tougher Blind Rivet Connections Goebel Fasteners

In This Video One Of Our Resident Fastener Specialists Talks About How You Can Remove Installed Pop Rivets Blind Rivets Are Considered Drill Bits Pop Surface